Wicks

We produce all standard and non-standard types of candle wicks, oil lamp wicks, catalytic aroma lamp wicks and wicks for other applications.

Technology

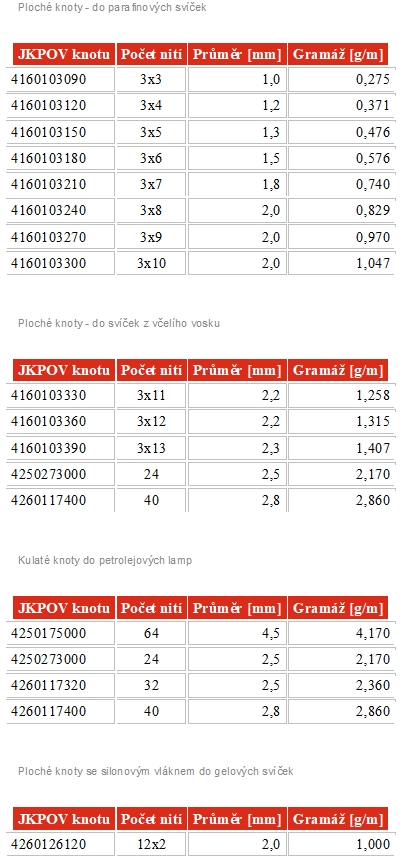

Manufacturing technology of flat and round wicks consists of interlacing yarns with different number of threads.

Material

The vast majority of wicks are made of 100% cotton. In addition, silicon, paper or, for example, gold wire are used in composite wicks.

Treatment

Greige wicks go through several levels of chemical adjustments:

- Refining – cleaning the yarn in a wick from badly combustible stems

- Dyeing – oxidative cleaning of the wick resulting in whitening

- Impregnation – chemical treatment of the wick to increase the efficiency of initial combustion

- Finish (eventual – on customer’s request) – application of thin layer of wax on the wick

Delivery:

Usually, the wicks are delivered on spools of 400 m – 1200 m. We can also cut them to desired lengths or deliver them on big drums up to 10,000 m and more. The most widespread types of wicks can be purchased on our e-shop or ordered via telephone at our dealers.

WHAT IS A WICK?

Wick is a strip of fabric of cylindrical or flat cross section which serves to convey liquids by capillary rise. It is used in liquid fuel light bodies, to transport lubricating oil and can supply water for irrigation.

Method

Wick is based on the capillary phenomenon. Liquid in the wick itself rises to certain height. If it is removed in some way, another liquid is sucked in. It can be removed by evaporation, burning, sucking into another medium (soil in a pot) or by dropping at location below the level of the incoming liquid (some types of wick lubrication).

Use

Oil lamp, petroleum lamp, candle, wick lubrication, self-watering flowerpot

Candle

Simple light source that has been used since antique times. It works on the principle of converting chemical energy, bound in the solid body of the candle (that is, in its fuel), to light energy. It consists of candle body, a wick and possibly a cup The body is made of flammable material and is usually of cylindrical shape. It may also have different rotationally symmetrical shape, such as the shape of a cone. But also shapes of a pyramid, a prism or other irregular shapes are used, especially in the so-called “decorative candles” (figures of people, animal figures, hearts, bells, Christmas trees, etc.) Flammable wick is placed in the center of the candle’s body. As flammable material, beeswax, paraffin, stearin, candle gel, tallow (or other solid fat – like fish or whale) can be used. Wick is usually made of plant textile material. Candle was one of the most important artificial sources of light (beside torches and oil lamps) until the discovery of kerosene, coal gas and electric lighting fixtures.

Principle of a candle

Wick sucks flammable material from the body of the candle that melts with the flame heat of the candle. On the surface of the wick then the combustible vapours evaporate and burn (or oxidize). By consuming the fuel (combustion), the candle gradually decreases. Modern candles are equipped with a knot, which, during burning, twists into the edge of the flame and burns there. With candles used in the past, the wick had to be cut off.

Specifications

Modern candle usually burn at a rate of 0.105 g/min. It produces an amount of light corresponding to roughly one lumen. Lighting efficiency is about a thousandth of light bulb. The colon temperature of the light is around 1000 K. The warmest is the flame above the dark blue part on one side of the flame (around 1400 °C). However, this part of the flame is very small, and so little thermal energy escapes. The temperature of most of the flame is around 1000 °C. Burning time of a 16g tea candle is between 4 and 5 hours. Ideal candle is adapted to the environment in which it is supposed to be used. It is a nonsense to use candles intended for the interior on the cemetery – most of them will burn badly. Cemetery candles, on the contrary, burn in the interior too well and can cause a fire.

HOW TO CHOOSE THE RIGHT WICK

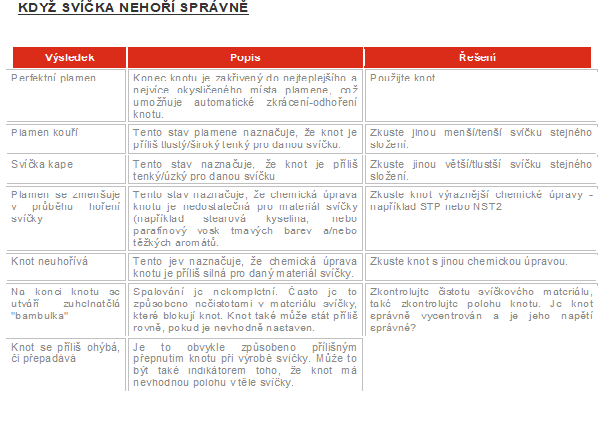

Wick is the most important element of home-made candle. While the shape, size, colour, scent and type of wax are the most obvious features of most candles, it is a wick that determines how well candle burns and what flame and light it provides. Using the thickness of the candle’s knot we can determine the size of the flame. Stronger candle gives the wick more fuel and results in greater flame, but it can also mean that the candle burns too fast.

Dependence of the thickness of a wick on the thickness of a candle

Even professional manufacturers sometimes find it difficult to estimate the correct wick for their candle. The candle either drips from the outside, or vice versa, the wick quickly burns down and the candle forms a crater. The problem can be caused by using too thin wick on the candle’s diameter as it burns faster than it can burn down so large dose of paraffin. Or, on the contrary, it burns down all the paraffin around and is not able to burn out. In addition, such a candle smokes unpleasantly. The whole situation is also influenced by the quality and composition of used paraffin, the amount of oil and so on. We also tested wicks from other manufacturers, for example German wicks which are said to burn faster. And the result? Totally identical quality with the wicks of our production.

Thickness of the wick, depending on the thickness of the candle depending on the use of different types of paraffins, must be tested for a long time and then you should create your own standard which must be followed forever. Nowadays we offer stronger wicks for large garden candles and oil lamps.

Choosing the right wick to match many combinations of waxes, additives, perfumes, colours and gels available on today’s candle market may require some time and effort. Choosing the right wick is perhaps the most important decision of the candle maker. It is imperative to choose the right wick so that the candle burns slowly with bright flame with a minimum of smoke and soot. Keep in mind, good candles require good wick.

Learn how to choose the right wick for your candle manufacture.

Suitable wick is essential for the candle to burn properly – slowly, evenly and without smoking. Higher quality wicks are typically knitted, wicks of lower quality are usually twisted. Wick controls the rate of burning and purity of the candle flame. If wick is too small, the flame will be smaller and it will melt smaller part of wax. This will cause the candle to quench itself. The wick which is too large for the candle if it melts too much wax and overwhelms the flame.

The wick choice is determined by a number of factors, such as diameter of the candle, type of wax used (beeswax, soy, gel, paraffin), additives (fragrances or dyes) and the container used to place the candle. Depending on the type of the wax, the same diameter of a candle may require different type of wick. For example, beeswax candles require thicker wick than paraffin candles of the same diameter. Although there are more than 100 different types of wicks, they fall into three main categories: flat, square, and tubular. Most flat and square wicks are made of cotton or of combination of cotton and paper and are soaked in salt solution to minimize smoking. Tube wicks are made with zinc or tin center surrounded by paper or cotton. Tube wicks are the toughest of all three groups.

The most common type of wick is flat wick consisting of three strands of cotton. Flat wicks are mainly used for smaller conical candles. Square wicks are stronger. Almost always are used for beeswax and larger candles. These wicks are ideal for candles of larger diameters, because production of larger flame ensures that the candle does not dissolve faster on one side than on the other. Beeswax candles burn and melt slower than paraffin candles, which is why stronger and larger wick (with bigger flame) is the best choice. Tube wicks remain upright when the candle burns. They are primarily used for votive, pillar, floating candles, tea candles and candles in glasses or other containers. Metal core wicks are hotter and they are good choice for gel candles that burn slower than paraffin candles and require higher temperatures to melt.

Waxes

There are several different types of waxes for candle making. It’s important what kind of wax do you choose, because wax serves as candle’s fuel. There are many different types of waxes to choose from, and each one has its unique qualities. Choose the wax according to the appearance and effects you want to achieve. Different types of waxes often have different melting points. Melting point is the temperature at which wax is transferred from solid to liquid form. It is important to know the melting point of the wax you choose because wax must be poured when the temperature reaches certain value. In addition, wax having particular melting point is often used for particular types of candles. Paraffin wax, which is a byproduct of oil, is one of the most popular type of waxes used for candles.

There are different types of paraffin which are divided by their melting temperature.

- Paraffin with low melting point melts at lower temperature than other paraffin types. It can dissolve at or below 55 °C. This type of paraffin is very soft and is suitable for making candles in containers. Because it is so soft, it is not recommended for shaped or carved candles.

- Paraffin, that is in the middle , melts when it reaches the temperature in range of 55-63 °C. This type of wax is also too soft to produce shaped or carved candles, so it should only be used for cast candles.

- Paraffin with high melting point melts at the maximum temperature of 63-66 ° C. Harder wax is suitable for carved and shaped candles and has longer burning period.

- Myrica Cerbera – wax is made when the berries from this plant are cooked. It is very fragrant and has beautiful shade of green. People who make old-fashioned candles from the past era often use this type of wax, but this is not affordable for many people. When you use 15kg of berries, you get 1kg of wax, so it’s very expensive. Melting point of this type of wax is approximately 48 °C.

- Tallow is also natural type of wax, which was first used centuries ago. Tallow is made from the fat of sheep, pigs and cows. It is colourless but often produces an unpleasant odour and smoke during combustion. It is soft wax with low melting point and is ideal for making candles in containers.

- Soybean wax is rapidly gaining popularity. From soybean you can get purely combusting, cheap, natural wax which can be used without additives necessary for change of colour, hardness, or clarity. Melting point of soybean wax is 49-82 ° C, depending on mixture. Unlike paraffin, soybean wax contains natural oils that mix well with fragrant oils. That’s why soybean wax holds fragrance better than paraffin, and it shrinks very little during candle making. In addition, soybean wax does not require tapping to remove air bubbles. Air pockets are rarely formed in this type of wax.

- Beeswax is popular natural form of wax. Many people use beeswax because it is naturally sweet, practically smokeless, and it burns very slowly. The melting point of this type of wax is approximately 65,5 °C. However, because it is natural product obtained from bees, it can be very expensive. Pure beeswax is sticky, so this type of wax is ideal for candles that are not shaped.

Most candles would require the use of wax additives. Some ingredients change flammability, brightness, colour and scent of the wax. With this in mind, choose the wax and all necessary ingredients carefully, to give your final candles the best overall burning quality and appearance.

BEEKEEPERS ADVICE BEEKEEPERS

How to improve quality of candles and beeswax

There is high demand for candles with figurative motives. Customers buy them as small Christmas gifts, others appreciate the scent of beeswax. It is known that beeswax candles will last longer – more precisely, they will burn longer.

Candle quality on the market is very diverse. In addition to yellow quality candles, candles of various shades of brown, often with grey or greenish shade, are commonly found. Another major drawback is large down flow of candles, especially with candles with figural motives.

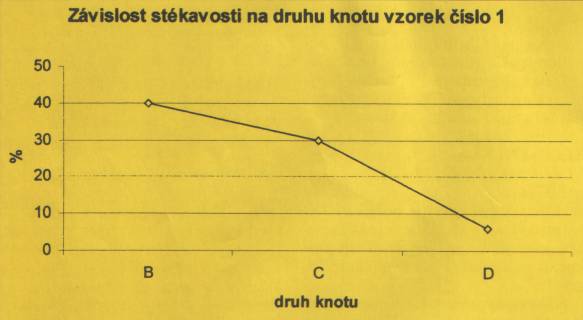

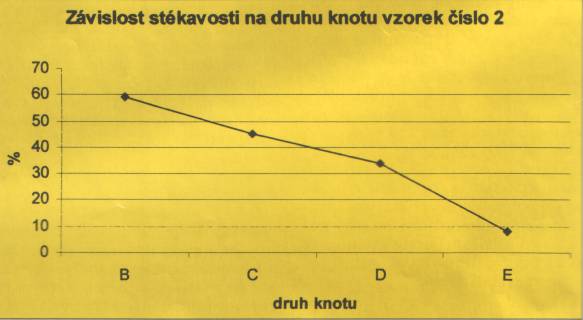

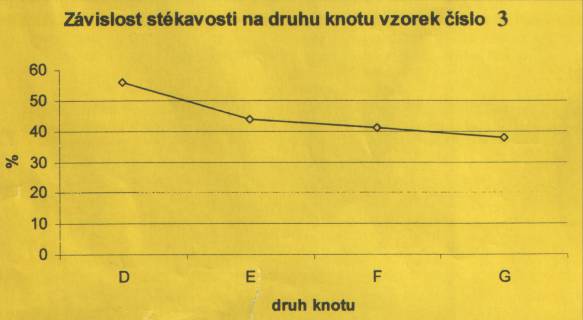

When the candle burns, sometimes large amount of wax drips, which reduces burning time, and it can also drip out of the candlestick and contaminate surrounding objects or blankets. In order to eliminate or at least significantly reduce this phenomenon, it is necessary to systematically deal with each type, in particular with the fact that the selection of wick affects the down flow and burning time of candle. To produce quality candles, you need to find out which kind of wick brings the best results.

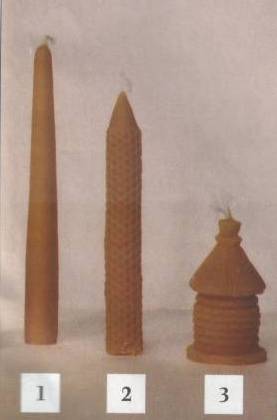

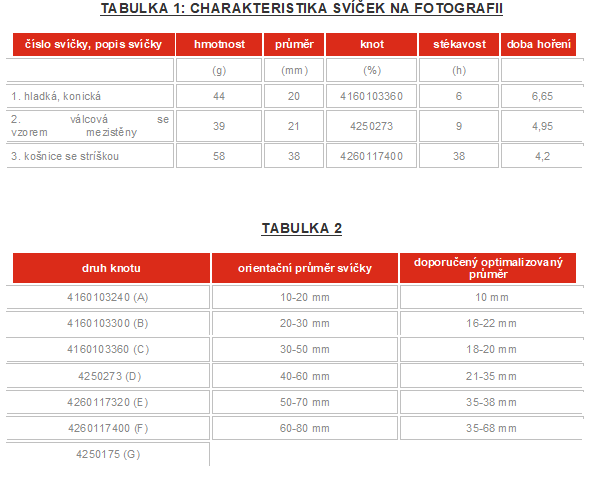

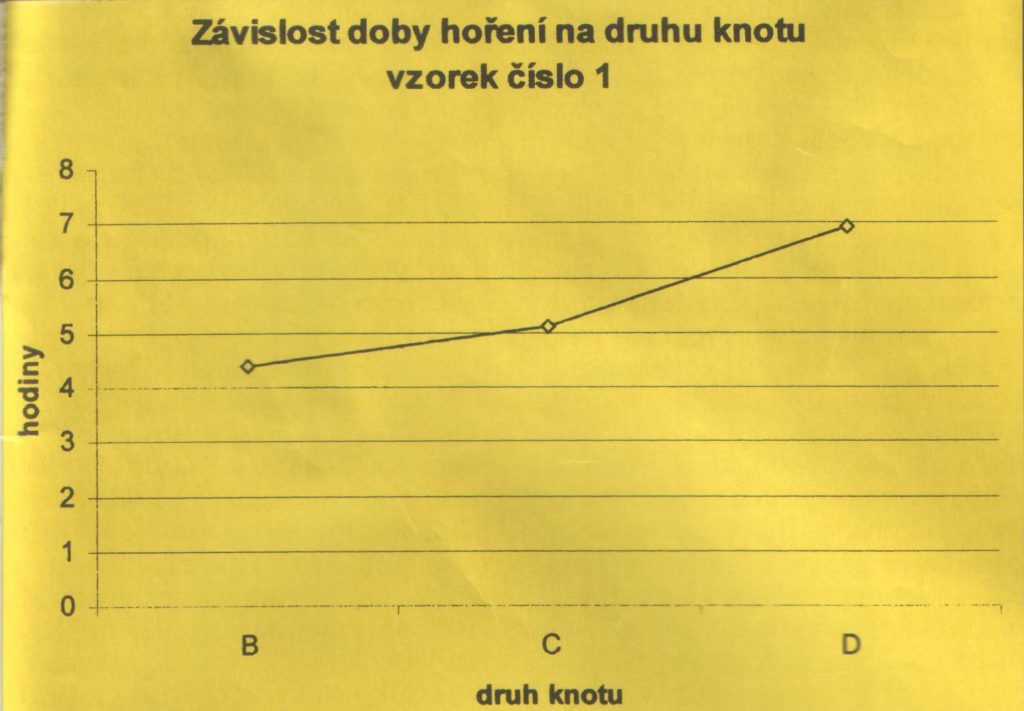

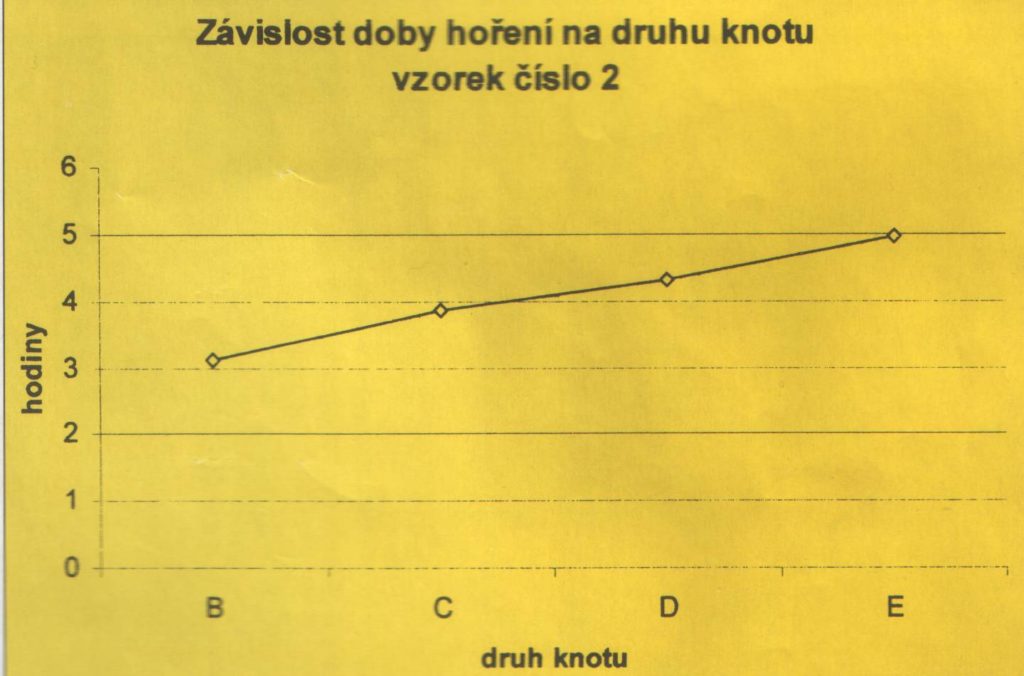

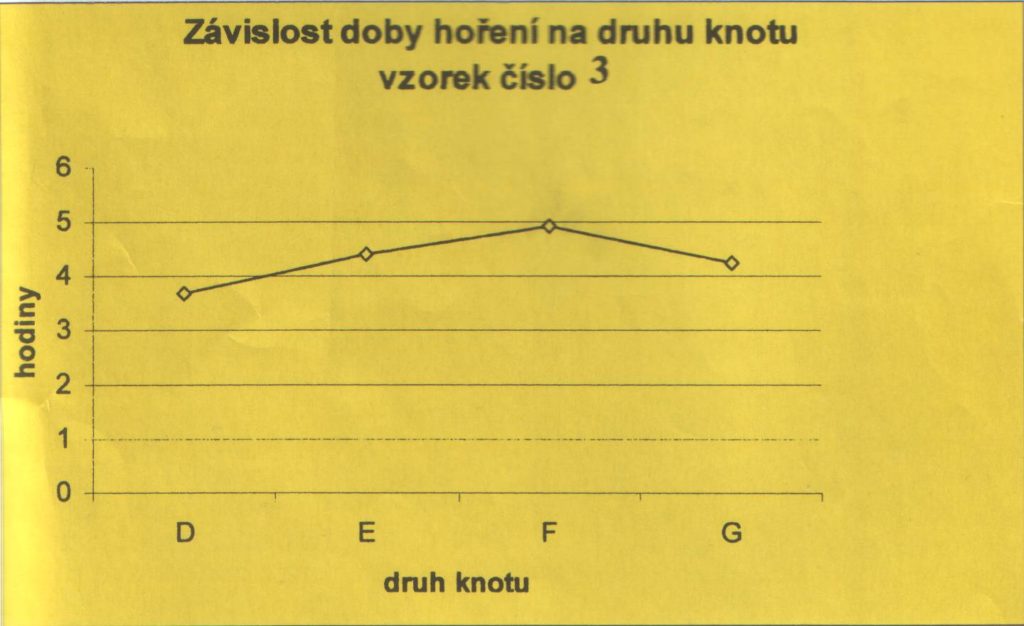

Different wicks were used for each candle (see Table 2) and down flow rate and burning time were measured. There are three types of candles on the photo (right). For these types, down flow and burning time with different types of wicks were measured. For all candles, it has been shown that increase in weight of the wick has always led to reduction in down flow and prolongation of the burning time. See relevant Tables.

Dependence of the down flow on the type of wick and on the burning time is given for these candles for illustration and easier understanding.

Candle’s Down Flow Measurement

We weigh the candle and its pad on analytical scale with precision of 0,01g. We use paper (i.e. for printers) as the pad. For small candles, a quarter of A4 size is sufficient, for more massive candles we use A4 size. After the candle burns away, we weight the remaining wax.

- Percentage of down flow = weight of remaining way x 100 / candle weight

Burning Time Measurement

The burning time is measured in hours.

- Burning rate [g/h] = candle weight – weight of the remaining wax / burning time [h]

From these graphs we can say, that the choice of stronger wick usually brings significant reduction in down flow and at the same time increase in burning time, which increases the utility value of the candle.

Why thin wicks are unsuitable?

At first sight it may seem that thin wicks are more economical because they have lower burning rate. Therefor it would be logical to think that it also mean longer burning time. In fact, radiant heat from candle’s flame melts more wax than the thin wick can burn. Melted wax accumulates and finally melts the edge of the candle with its heat, and melted, unused wax flows away without any benefit.

For candles with larger diameters, the heat of the flame is no longer sufficient to melt the edge. Burning wick with long burning time gradually gets smaller, the flame decreases and sometimes goes out. Disadvantage of stronger wicks, sized G and H, is enhanced soot formation. In addition, the wick sometimes slowly burns off and what remains is longer charred residue, which also increases the formation of soot. In such case, it is appropriate to trim the knot with scissors.

Which Wick to Use?

To facilitate the selection of suitable wick, see table 2 (above) for individual wicks optimized for particular candle diameters. They minimize down flow and prolong burn time. For candles with a diameter of more than 35mm, the down flow can not be significantly reduced by choice of the wick and it is assumed that it reaches 40% or more of the original weight of the candle.

Systematic tests on many kinds of candles have shown that the choice of wick has significant effect on the down flow and burning time of the candle. Significant improvement was achieved by choosing stronger wicks. For candles weighing over 50g, the down flow rate has not been reduced to significantly lower value.