Thanks to its remarkable strength (5 times harder than steel at the same weight) combined with high temperature resistance, it is popular material in a number of demanding applications.

KEVLAR® fibre is produced in the form of staple, infinite filament. It is used in optical cables as well as in composite structures for light armour vehicles, aircraft, boats and sports goods.

This fibre has excellent resistance to heat and flame and dominates the world market in particular in the field of protective clothing for firefighters, army and police.

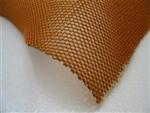

NOMEX® fibreprotects not only the lives of people but also helps to protect the environment. Can be applied in hot air filtration filters, as well as in laundries and cleaners, in ironing machines and so on. Lightweight and solid NOMEX® Honeycomb structures have found their place in the transport industry, for example, in the manufacture of ships, yachts and aircraft.

This material is a unique combination of mechanical properties. Density is lower than water density. Highest possible mechanical resistance. Elastic modulus is the second highest, right after special carbon fibre. Dyneema® fibre can absorb extremely high energy. This feature is used for ballistic protection products such as bulletproof vests, cut-resistant protective gloves, motor helmets, etc.

Dyneema® fibre is made of polyethylene and contains no chemical components, therefore it is a pure fibre with high resistance to water, moisture. It has very good resistance against chemicals, UV radiation and microorganisms.

The material is characterized by its high resistance to high temperature and self-extinguishing and high tensile strength. It is the toughest and strongest type of polyamide. Its main characteristic is high chemical resistance to fuels, oils, greases, most organic solvents and alkalis. Moisture absorption is lower than with PA 6.

Reflective materials work on the principle of backlight reflection, which is physical feature that ensures that the light rays falling down on the surface of the reflective material are subsequently reflected and in narrow cone fall back directly into the source of the light. Reflective material will ensure noticeable visibility of the object under reduced visibility, thereby increasing safety and resolvability.

Reflection technology is based on a layer of microscopically small glass beads provided with a mirror surface on the back which are attached to the underlying fabric layer. These beads are then responsible for the light falling on retroreflective material being reflected back to the source after a double fracture.

Due to its excellent reflective efficacy, excellent performance and compatibility, it is designed especially for applications for work, sports and rubber footwear, bags, rucksacks and other products, designed to make the object visible and thus increase its safety and resolvability.